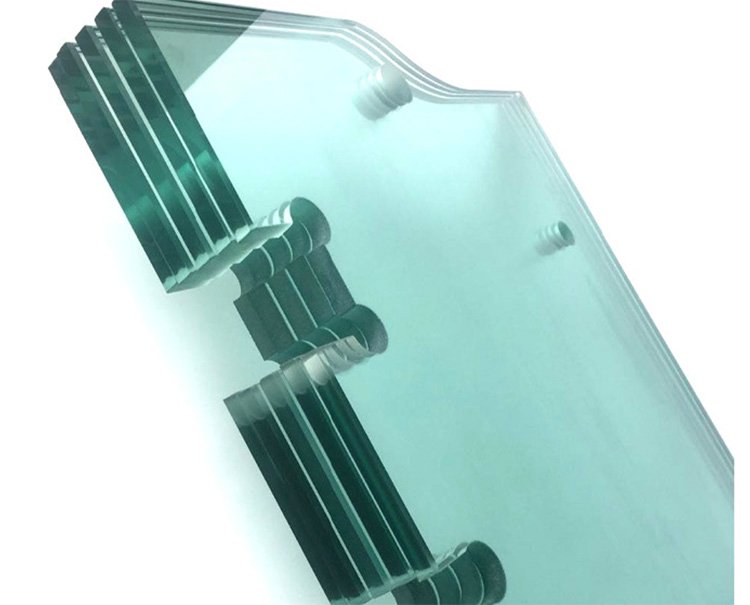

19mm Low Iron Toughened Glass

It is processed by heating 19mm low iron/extra clear/ultra clear/Starphire/Crystal/super clear/super white glass to 650 degrees softening point and then quenched rapidly. It creates tension inside the glass and compression outside the glass surface.

Heating Time

19mm clear/low iron/extra clear/ultra clear/Starphire/super clear tempered glass in Radiant furnace: 39s/mm, total 735 seconds~745 seconds

19mm clear/low iron/extra clear/ultra clear/Starphire/super clear toughened glass in Forced Convection furnace: 28s/mm, 523 seconds~533 seconds

Quench Time

19mm low iron toughened glass Quench Time=Glass Thickness^1.8=19mm^1.8=200s

Compression & Tension Zone

21% (3.99mm) up & down part with compression, 58% (11.02mm) middle part with tension.

Surface compression >90Mpa (over 13000Psi).

19mm Toughened Glass Standard & Certificate

North American

ASTM C1048 standard, SGCC certificate

Europe

EN12150 standard, CE certificate

Australia & New Zealand

AS/NZS2208-1996 standard, AS/NZS 2208 certificate

Features & Benefits

High Clarity

19mm low iron glass has a 90% visible light transmission, which creates a stunning and unmatched appearance.

Low Spontaneous Breakage

Less than 120ppm iron content and super low NiS, which lower the spontaneous breakage down to 0.01%.

Flatness Quality

<0.2% local bow & <0.3% arc bow standard, with non-visual defects in the surface.

Flexibility

3~5 stable cooperative factories to guarantee lead time based on different requests.

Turnkey Solution

From smaller size glass louver to giant glass 3660mm*18000mm toughened glass.

Safety

when 19mm extra-clear tempered glass panel is broken, it will break into granularities to prevent series of injuries.

Strength

19mm ultra-clear toughened glass is about 4~5 times stronger than 19mm clear float glass.

Stability

19mm Starphire toughened glass can withstand 280℃ temperature variation.

Applications

Glass Balustrade

Glass Bridge

Glass Cylinder

Glass Elevator

Glass Facade

Glass Fin

Glass Mould

Glass Skylight

Glass Stair Tread